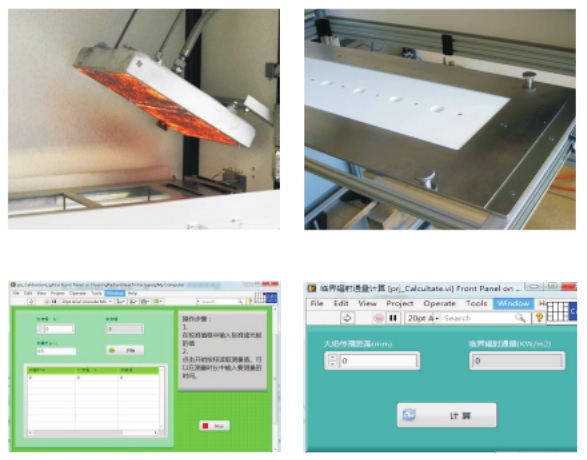

Flooring Radiant Panel Test Apparatus

According to

ISO 9239-1, ASTM E648, NFPA 253

Flooring Radiant Panel Test Apparatus is developed according to ISO 9239-1, ASTM E648 and NFPA 253 floor material combustion performance test method. It can be used to determine the critical heat radiation flux of carpet, floor material and roof insulation material when the flame stops spreading transverse. At the same time, the smoke density development state of the material in the combustion test process can be detected.

Flooring Radiant Panel Test Apparatus consists of

·Stainless steel test chamber with front door for easy cleaning and specimen replacement. The test chamber consists of a 13mm thick calcium silicate board and a 110mm x 1100mm fire-resistant glass, installed in front of the test chamber to observe the entire length of the specimen during the testing process.

· The circulating air volume between the test chamber and the specimen is generated by 0.23m2 on both sides of the specimen.

· The radiation heat panel is placed on the specimen holder, with its long side at an angle of (30±1)°to the horizontal plane. The board should be able to withstand temperatures exceeding 900℃.

· The radiation heat panel is automatically ignited by high-voltage pulses, ensuring stable ignition and safety. And equipped with a flame detection device, there is an alarm reminder in case of abnormal fire extinguishing and the gas source is automatically cut off to ensure the safety of the test.

· OMEGA radiation pyrometer measures the flame temperature of the radiation panel, equipped with two thermocouples to measure the temperature inside the test chamber and flue respectively.

· T-shaped stainless steel porous burner, with 19 uniformly distributed holes with a diameter of 0.7mm on the centerline, and 16 holes with a diameter of 0.7mm distributed 60° below the centerline. Cylinder push mode, high-pressure pulse automatic ignition, stable ignition, safe and reliable. Automatically apply flames to the specimen during programming time.

· Equipped with a heat flow meter to calibrate heat flux, the heat flow meter calibration adopts a mobile lifting mode. Users can move the heat flow meter and conveniently calibrate the radiation plate heat radiation flux. At the same time, the testing software can draw the heat radiation flux curve.

· Equipped with a standard porous calibration plate device, the drawer device is designed to facilitate the clamping, retrieval, and placement of calibration plates and specimens.

· The silicon optical amplifier device converts the optical signal variation into an electrical signal and outputs it.

· Equipped with standard filters to calibrate the accuracy of the optical path.

· It can automatically collect, calculate, save, and output data reports, display real-time data and smoke density curves/historical curves and data display and query.

If you have a particular need for fire test instruments or are just in the planning stage, let's contact us.